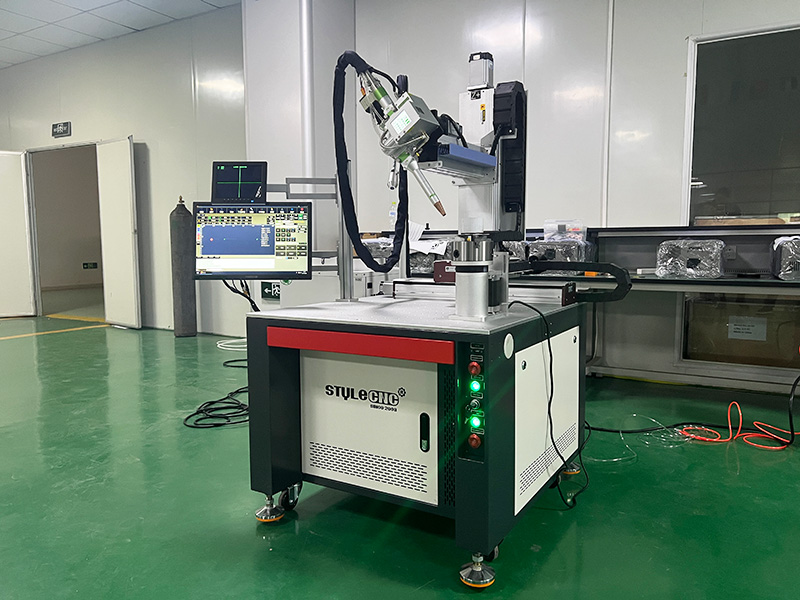

高精度全自動數(shù)控激光焊接機出售

數(shù)控激光焊接機是一種采用高功率光纖激光束焊接系統(tǒng),用于對接縫、搭接縫、點焊、T型對接、吻焊、線焊、環(huán)焊、搭接、搭接邊、法蘭接頭等精密金屬焊縫的自動激光焊接機。 LWT2000是電子元器件、珠寶首飾、手機電池、鐘表、傳感器、精密機械、通訊設備、藝術(shù)品、工藝品、高檔家具櫥柜、電梯配件等精密焊接的必備工具,價格實惠,在8,800美元到11,300美元之間。

- 品牌 - STYLECNC

- 型號 - LWT2000

- 激光光源 - 銳科、IPG、 MAX

- 電源選項 - 1500W, 2000W, 3000W

- 每月有 320 件庫存可供銷售

- 符合質(zhì)量和安全方面的 CE 標準

- 整機一年有限保修(主要部件可延長保修)

- 購買產(chǎn)品可享受 30 天退款保證

- 為最終用戶和經(jīng)銷商提供終身免費技術(shù)支持

- 線上(PayPal、阿里巴巴)/線下(電匯、借記卡和信用卡)

- 全球物流和國際運輸至任何地方

什么是自動激光焊接機?

自動激光焊接機是一種計算機數(shù)控激光焊接機,可進行自動或半自動的對接焊、密封焊、點焊、搭接焊,并實現(xiàn)復雜平面直線、圓弧、任意軌跡的焊接。

A數(shù)控laser welding machine is an automated high-precision fiber laser beam welder to joins pieces of metal together for cell phone batteries, jewelry, electronic components, sensors, watches, precision machinery, communications, handicrafts, high-end cabinets, elevator accessories, stainless steel door handles, high-end furniture, and stainless steel hip flasks.

An automatic數(shù)控laser welder can easily perform welding between carbon steel, alloy steel, stainless steel, and other different steels, as well as stainless steel-nickel alloy, nickel electrode-cold forged steel, bimetallic strips with different nickel content, titanium, nickel, tin, copper, aluminum, and welding between chromium, niobium, gold, silver and other metals and their alloys. In addition, it can also handle the welding between copper-nickel, nickel-titanium, copper-titanium, titanium-molybdenum, brass-copper, carbon steel-copper, and other dissimilar metals.

Features & Advantages of Automatic Laser Welding Machine with數(shù)控Controller

全自動光纖激光焊接機具有操作簡單、焊縫美觀、焊接速度快、無耗材等特點和優(yōu)勢,可以完美替代傳統(tǒng)的氬弧焊、電焊。

? 完美替代氬焊和電焊,用于不銹鋼、碳鋼和鋁等薄金屬焊接。

? 自動化激光焊接機可24小時連續(xù)穩(wěn)定工作,滿足工業(yè)量產(chǎn)制造的需求。

? 重量輕、體積小、符合人體工程學的設計,操作舒適。

? 采用PC機控制,專用軟件輔助,簡單易學,可使工件作平面軌跡運動,焊接任意點、直線、圓、方形,或由直線與圓弧組成的任意平面圖形。

? 焊頭內(nèi)部結(jié)構(gòu)完全密封,避免光學部分受到灰塵污染。

? 激光光束質(zhì)量優(yōu)良,焊接速度快,焊縫牢固美觀,為用戶提供高效的焊接項目。

? 電光轉(zhuǎn)換率高、能耗低、無耗材、體積小,長期使用可以為用戶節(jié)省大量的加工成本。

? CCD 液晶監(jiān)控觀察系統(tǒng),可根據(jù)紅燈指示觀察產(chǎn)品定位及焊接效果。

? 焊縫美觀、速度快、無焊接痕跡、不變色、無需后期打磨。

? 光纖輸出可配備機器人或流水線。

? 我們有很強的為客戶定制特殊機型的能力,可以根據(jù)客戶的需求進行量身定制。

? 焊縫細、焊接深度大、錐度小、精度高;外觀光滑、平整、美觀。

? 多語言顯示,支持國際應用。

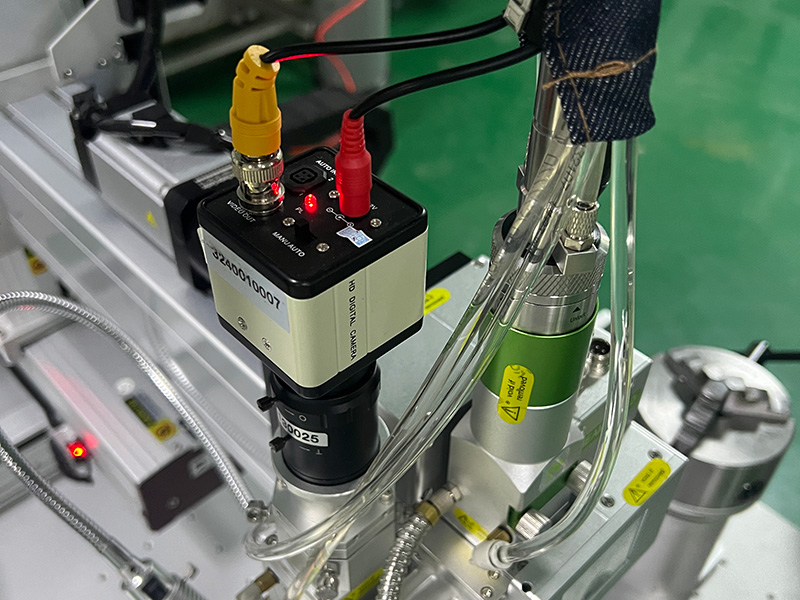

? 搖擺焊接頭在高反材料焊接中具有很強的優(yōu)勢,應用范圍廣泛,性價比很高。

? 焊頭采用電機驅(qū)動X、Y軸振鏡,具有多種擺動方式,可針對不規(guī)則形狀、較大焊點等加工參數(shù)設置,明顯提高焊接質(zhì)量。

? 保護鏡采用抽屜結(jié)構(gòu),更換方便,可配多種QBH接頭激光源。

? 焊接頭配備風幕組件,減少粉塵及飛濺殘留物的污染。

? 抗干擾能力強,配置 1000W-2000W 激光器。

Automatic數(shù)控Laser Welding Machine Technical Parameters

| 型號 | LWT1500 | LWT2000 | LW3000 |

| 激光功率 | 1500W | 2000W | 3000W |

| 焊接深度 | 截面積≤3mm 鋁≤3mm | 截面積≤4mm 鋁≤4mm | 飽和度≤6mm 鋁≤6mm |

| 激光波長 | 1080±10納米 | ||

| 纖維長度 | 10 m | ||

| 工作表 | 500 *300 * 300mm | ||

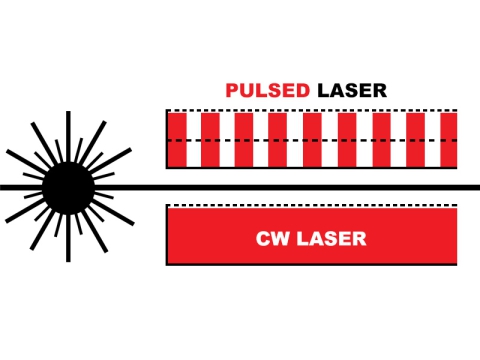

| 脈沖寬度 | 持續(xù) | ||

| 瞄準 | CCD | ||

| 駕駛系統(tǒng) | 滾珠絲杠+伺服系統(tǒng) | ||

| 冷卻冷水機 | 工業(yè)冷水機 | ||

| 工作電壓 | 220V/ 2P 為 1500W,2000W 380V/3P 用于 3000W | ||

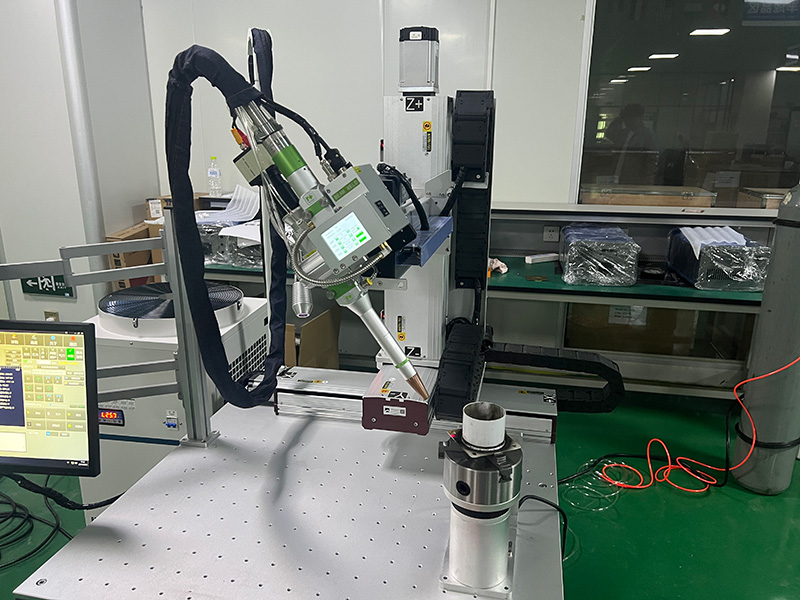

數(shù)控Automatic Laser Welding Machine Details

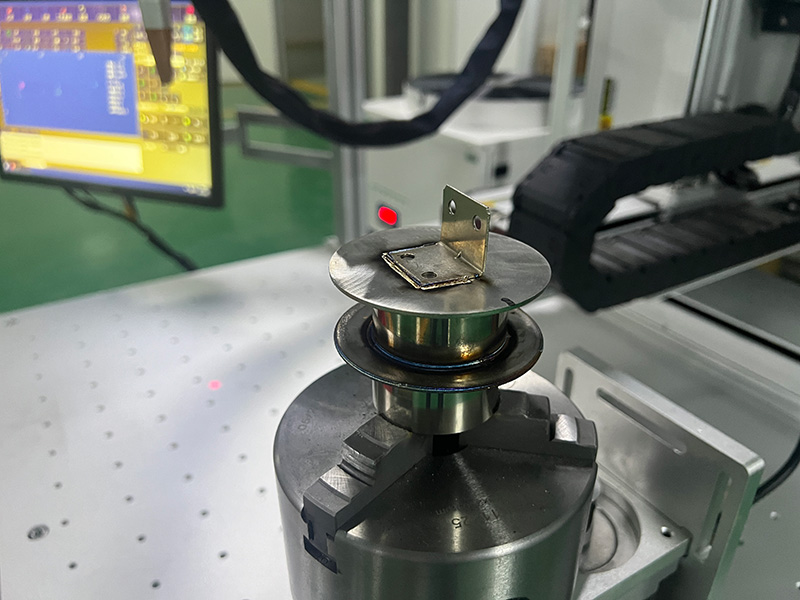

擺動激光焊接頭

焊縫干凈美觀、速度快、無焊痕、不變色、無需后期拋光。

CCD 相機

A CCD 帶有藍光燈的攝像頭使焊接件清晰可見。

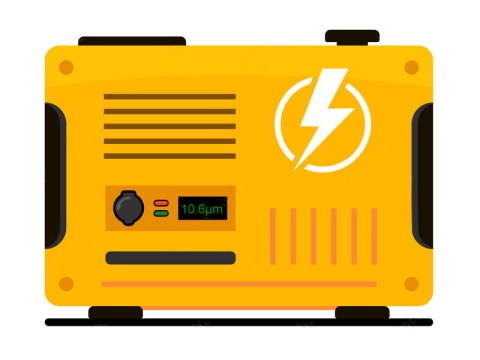

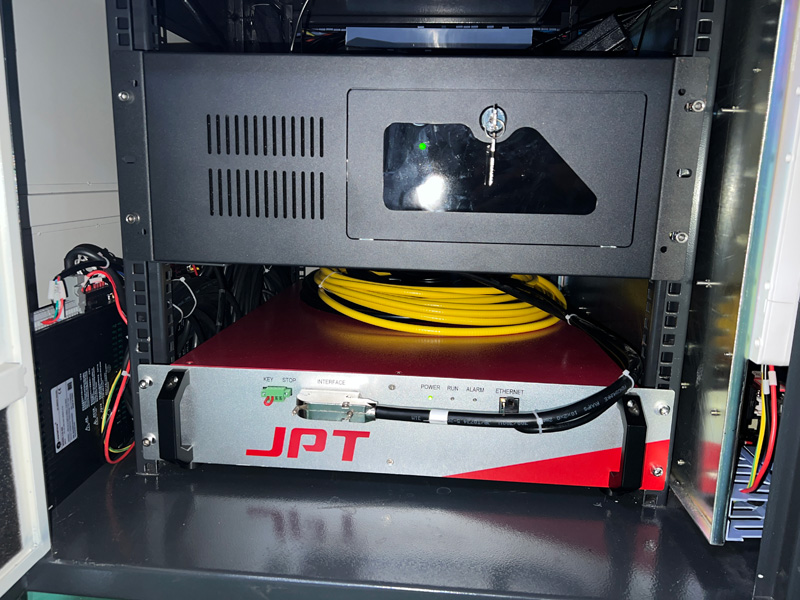

光纖激光發(fā)生器

最好的品牌激光源。

使用壽命長,故障率低,防反射。

交互式控制系統(tǒng)使光斑更大,焊縫形成得更好。

數(shù)控控制器

操作簡單,對操作人員的要求低。

X、Y、Z 軸導軌

具有上下移動功能,可焊接不規(guī)則產(chǎn)品,Z軸具有剎車功能。

冷水機

冷水機有助于冷卻激光頭。

所選擇的功率取決于激光源的功率。

Automatic數(shù)控Laser Welder Applications

數(shù)控automatic laser welder is mostly used in the automobile manufacturing industry, lithium battery industry, pillow plate heat exchanger, machinery manufacturing industry, furniture industry, sheet metal fabrication industry, power battery, electronic communication industry, metal connectors, kitchen and bathroom electrical equipment, mobile phone accessories (medium plate, nut), hardware, structural parts, automotive parts, medical equipment, and more precision parts. The automatic fiber laser welder is suitable for continuous welding of various metals like stainless steel, carbon steel, aluminum, copper, and titanium.

自動光纖激光焊接項目

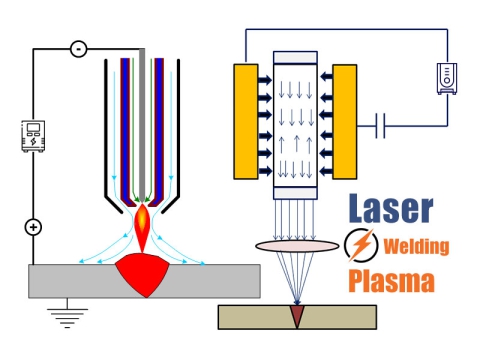

數(shù)控Laser Welding vs. Traditional Welding: What's the Difference?

數(shù)控laser welding and traditional welding are 2 distinct methods used for joining metal components, each with its advantages and applications. While traditional welding has been around for decades, laser welding is a modern alternative that offers higher precision, efficiency, and automation capabilities. Understanding the key differences between these methods can help businesses and professionals choose the best welding technique for their needs.

數(shù)控laser welding utilizes a highly concentrated laser beam to fuse metals with pinpoint accuracy. This method produces minimal heat-affected zones, reducing warping and distortion in delicate materials. It is ideal for industries that require precision welding, such as aerospace, medical device manufacturing, and electronics. Additionally,數(shù)控laser welding can be automated, allowing for consistent results and reduced labor costs. However, the initial investment in laser welding equipment is high, making it more suitable for high-value or mass-production applications.

另一方面,MIG、TIG 和電弧焊等傳統(tǒng)焊接方法使用熱量和填充材料來連接金屬。這些方法由于其多功能性和經(jīng)濟性而被廣泛應用于建筑、汽車維修和重型制造。傳統(tǒng)焊接可以處理較厚的材料,并且在戶外環(huán)境中效果很好,但它通常會產(chǎn)生更多的熱變形,并且需要熟練的勞動力才能獲得高質(zhì)量的結(jié)果。雖然傳統(tǒng)焊接設備的前期成本較低,但它涉及電極、焊劑和保護氣體等消耗品的持續(xù)成本。

Safety Tips for Operating an Automatic數(shù)控Laser Welding Machine

Operating an automatic數(shù)控laser welding machine requires strict safety measures to prevent injuries and ensure optimal performance. Since laser welding involves high-intensity beams, extreme heat, and electrical components, following proper safety protocols is crucial. Here are essential safety tips to keep in mind.

? 務必佩戴專為特定激光波長設計的激光安全護目鏡,以保護您的眼睛免受有害輻射。此外,請使用耐熱手套、防護服和面罩,以防止灼傷和暴露于強光下。

? 激光焊接會產(chǎn)生煙霧和蒸發(fā)的金屬顆粒,吸入后可能有害。使用有效的煙霧抽取系統(tǒng)或在通風良好的環(huán)境中工作,以盡量減少接觸有害排放物。

? 開始前,請確認機器設置與材料和焊接規(guī)格相匹配。不正確的設置可能會導致焊接質(zhì)量差或因過熱和功率輸出過大而造成安全風險。

? 確保焊接的金屬件牢固夾緊,以防止在操作過程中發(fā)生移位。不固定的材料可能導致錯位、焊接不良或意外暴露于激光束。

? 由于激光焊接會產(chǎn)生高熱,請將工作區(qū)內(nèi)的所有易燃物品(如紙張、油和溶劑)移走。這有助于降低火災風險并確保更安全的工作環(huán)境。

? 激光束可能會從高度拋光的表面反射,對附近的操作員造成危險。使用適當?shù)钠帘位蚍婪瓷渫繉涌勺畲蟪潭鹊亟档鸵馔饧す庹丈涞娘L險。

? Regularly check the machine's optics, cooling system, and electrical connections to ensure smooth operation. A well-maintained數(shù)控laser welding machine reduces the likelihood of malfunctions and extends its lifespan.