Wood數控machine is a type of computer numerical controlled power tool for woodworking, which is mostly used in popular woodworking to take the place of manual actions. When you have an idea to buy it, you can follow the buying guide to find the best數控machines for woodworking.

A wood數控machine is composed of computer,數控controller, and machine parts. It is designed and typeset through the special engraving software configured in the computer, and the design and typesetting information is automatically transmitted to the數控controller by the computer. The controller converts this information into a signal (pulse train) with power that can drive a stepper motor or a servo motor, and controls the數控machine to generate the X, Y, and Z axis tool path. At the same time, the high-speed spindle cuts the obeject fixed on the worktable of the machine through the tool configured according to the material. It directly supports G code formats generated by UG, ArtCAM, Type3, CorelDraw, Proe and other CAD/CAM software, and can make various flat or 3D designs of patterns and texts in the computer, and realize the automatic數控machining operation.

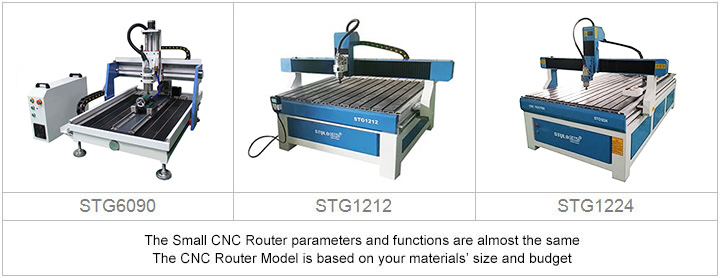

If you are engaged in woodworking of arts, gifts, crafts, signs making, marks, logos making, mold making, models, boxes, if you are working in small business, home business, small shop, home shop or hobbyists, a 業余愛好wood數控machine for beginners is your best choice.

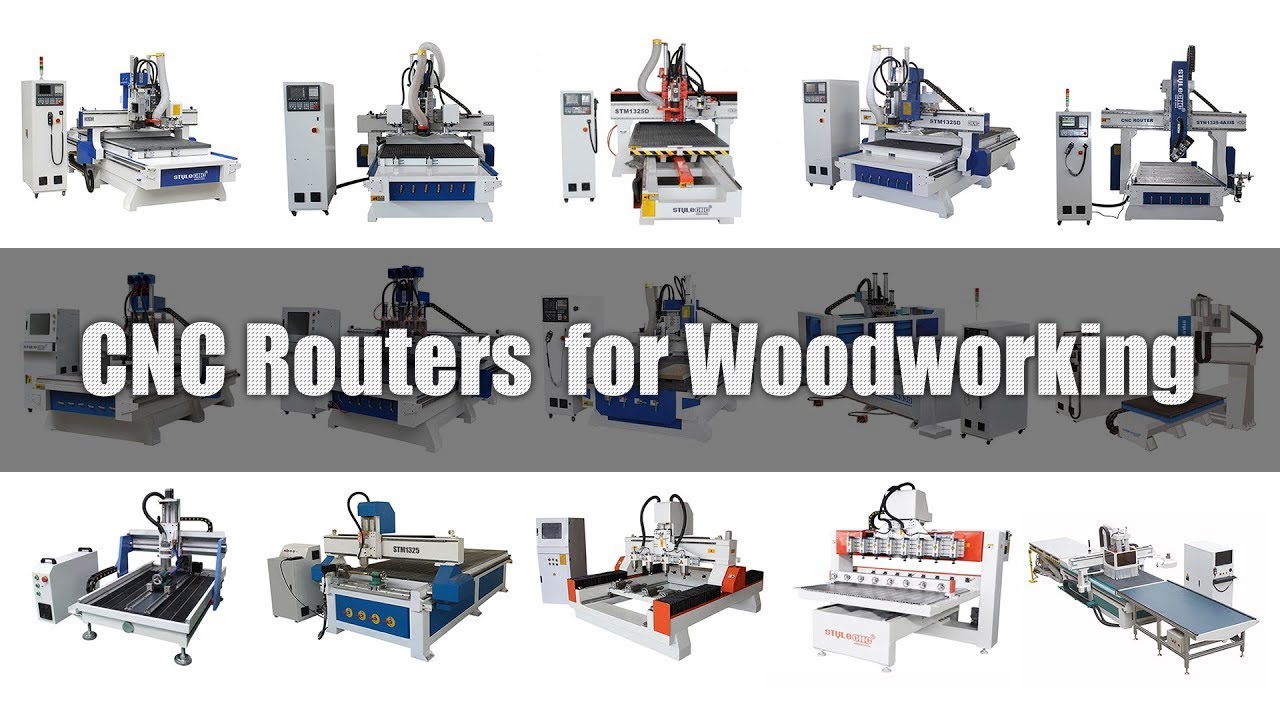

Hobby數控Machines

工作臺尺寸:2x2、2x3、2x4、4x4

數控Controller: DSP, Nc-studio, Mach3

價格范圍:2,500.00 美元 - 5,000.00 美元。

Working Area: 600*600mm, 600*900mm, 600*1200mm, 1200*1200mm.

The technical parameters and functions of these數控wood machines are almost the same, the table size is based on your materials' size and budget.

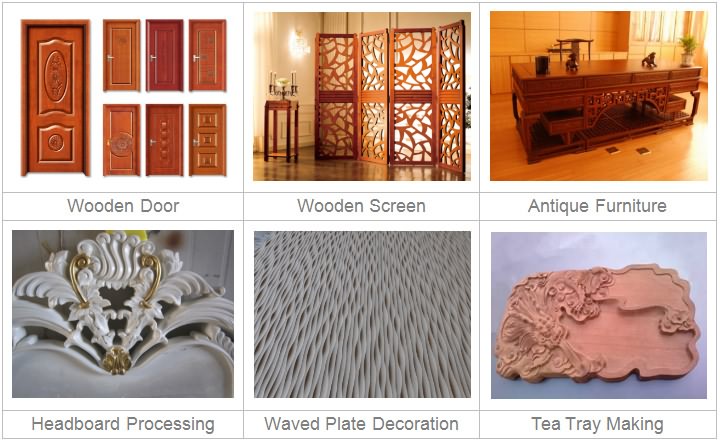

If you are working in woodworking business, such as solid wood door, craft wood door, MDF door, wood screens, windows, tables and chairs, cabinet, home furnitures, office furnitures, room decoration, etc. A standard 3 axis數控wood machine will help you to complete these projects, of course, it can do what a small hobby數控wood machine does.

3 Axis數控Machines

工作臺尺寸:4x6、4x8、5x10、6x12

數控Controller: DSP, Nc-studio, Mach3,新代

價格范圍:5,000.00 美元 - 10,000.00 美元

Working Area: 1300*2500mm, 1500*3000mm, 2000*3000mm, 2000*4000mm.

If you are in big scale processing for above woodworking, and your designs are complex need more than 1pcs wood數控machine kits to process, It is better for you to choose a 數控銑床 配有工具更換器。

In general, the自動換刀(Automatic Tool Changer)數控machine with 1300*2500mm size, because the table size is 1220*2440mm.

If your panel is special size, we also have 1500*3000mm, 2000*3000mm, 2000*4000mm working size for option.

自動換刀數控Machines

Pneumatic自動換刀數控Wood Routers with 2-4pcs Tools (Price Range: USD 7,000.00 - USD 10,000.00)

Disc and Linear自動換刀Wood數控Machines with 8-16pcs Tools (Price Range: USD 20,000.00 - USD 30,000.00)

If your wood works need to process the panel work above, and also need to do arc carving, such as wood moulds carving, a 4 axis swing head is needed. You can buy a 4 axis數控machine.

4 Axis數控Machines

工作臺尺寸:4x8、5x10、6x12

數控Controller:新代

價格范圍:20,000.00 美元 - 48,000.00 美元

Working Area: 1300*2500mm, 1500*3000mm, 2000*4000mm.

如果你的工作 3D 木制模具制作與所有方向的弧形雕刻,你應該買 5 axis數控machines.

5 Axis數控Machines

工作臺尺寸:4x8、5x10、6x12

數控Controller: Osai,新代

價格范圍:90,000.00 美元 - 200,000.00 美元

Working Area: 1300*2500mm, 1500*3000mm, 2000*4000mm.

If you are working in customized panel furniture production, we also have smart wood數控machines with automatic nesting software, the 自動套料數控machine has full functions of automatically loading, unloading, nesting, labeling, optimizing, vertical drilling, slotting, grooving, cutting, carving and engraving, etc.

Smart 自動套料數控Machines

工作臺尺寸:4x8、5x10、6x12

數控Controller:新代

價格范圍:5,500.00 美元 - 56,000.00 美元

Working Area: 1300*2500mm, 1500*3000mm, 2000*3000mm, 2000*4000mm.

How to Choose數控Machine Tools for Woodworking?

1. Determine the main technical parameters of the數控bit: The bit outer diameter, machining thickness, center aperture. Other technical parameters: number of tool teeth, rotation direction, rotation speed, feed speed, clamping method, tool tooth material.

2、選擇刀具的結構:根據切削對象的性質和要求,從技術、經濟2個方面選擇整體刀具、焊接整體刀具、組裝刀具和組合刀具。

3. Selection of tool rotation direction: The bit rotation direction is determined according to the rotation direction of the數控machine spindle and the relative position of the tool axis and the feed workpiece. Whether it is a whole tool or an assembled tool, the inclination of the cutting edge relative to the tool radius determines The direction of rotation of the bit.

4. Selection of數控tool consumption: The cutting consumption of the tool includes the cutting speed of the tool, the feed speed of the workpiece and the milling depth. The cutting speed of the tool depends on the speed of the tool and the radius of the tool. The feed speed of the workpiece depends on the requirements of the cutting surface quality. The surface roughness of the workpiece to be cut depends largely on the tool feed per tooth during the cutting process. If the feed per tooth is too large, the machined surface is too rough, and the feed per tooth is too small, and the machined surface will be burnt. Phenomenon, so the feed per tooth of the tool must be appropriate.

5、刀具運轉的穩定性:刀具運轉的穩定性是保證加工精度和表面質量的基礎。這包括2個方面:一是切削過程中刀具受外力激勵而產生的振動;二是刀具在外力作用下產生變形。

6、刀具加工的安全性:刀具加工的安全性包括刀具轉速的限制、切屑厚度的限制、成形刀具輪廓h8的限制、裝配刀具刀片厚度和延伸的限制。

木材切削的特點是高速切削,刀具轉速在3000rpm以上。高速切削給木材切削帶來高的生產效率和光滑的表面質量。同時也帶來了一系列的安全問題。因此,當銑床主軸轉速達到9000rpm時,除刀柄刀具小于等于XNUMXrpm外,應禁止使用組裝刀具。 16mm。整體刀具的焊縫也應進行嚴格的探傷檢查。切屑厚度限制是必要的措施,以確保刀具進給量不會過大而造成刀具嚴重過載。

對于成形刀具來說,成形輪廓輪廓度的h8值與刀具的裝夾方式、切削工件的厚度、刀具直徑等都有密切的關系。在工件厚度、刀具直徑、中心孔徑確定后,刀具的輪廓度h8反映了刀具本身的強度和剛度,以及承受切削阻力的能力。因此,必須對輪廓度h8進行限制,以保證刀具使用時的安全性。在設計裝配式刀體時,必須考慮刀片的夾緊問題。無論是圓柱形刀片還是盤形刀片,刀片的夾緊形式都必須保證它能提供足夠大的夾緊力,以抵抗旋轉的離心力。

購買指南

1、電機的功率是不一樣的,功率越大的越精細,所以在使用的過程中一定要看你是制作哪種類型的工藝品,如果想要做出的成品更加的精致,那么就一定要選擇功率大的。當然功率大的的價格也 數控機床 自然就比較貴了。

2、要了解主軸電機的轉速,它的轉速是可調的,在選購的時候如果發現轉速不可調或者可調范圍小的,建議不要選擇,因為在使用的過程中,會影響成品的品質。

常見問題

什么是數控機床?

A數控machine is an automated machine tool equipped with a數控control system. The control system can logically process a program with a control code or other symbolic instructions, decode it, express it with coded numbers, and input it into the numerical control device through an information carrier. After arithmetic machining, the numerical control device sends out various control signals to control the action of the machine tool, and automatically process the parts according to the shape and size required by the drawing.

What Is The Best Wood For數控Machining?

木材有軟有硬,一般來說,木材軟易雕,木材重難切雕。木材堅韌、紋理細密、色澤鮮艷的稱為硬木,如紅木、黃楊木、花梨木、杏木、胡桃木等,它們具備了加工的所有優點,是雕刻的上等材料,適合加工結構復雜、造型多樣的器物。制作精細的作品在制作和保存過程中不易破碎損壞,收藏價值較高,但耗費的人力和物力較大,容易損壞鉆頭。木材質地較軟的,適合初學者,如椴木、銀杏木、樟木、松木等。這類木材適合切雕結構簡單、形象較為一般的作品,也較容易切雕,但由于木材質地較軟,色澤較淡,有的需要上色處理,以增強體積感。有些木紋比較明顯,變化多端,比如水曲柳、松木、杉木等,可以巧妙地運用流暢的木紋和木紋的肌理,做出一些更具抒情意味的作品。一般來說,造型的起伏越大,木紋變化越豐富,韻味越濃;造型的線條越婉轉流暢,木紋走向的效果就越理想,甚至會出乎意料地好看,富有裝飾性。當然,這類木材的設計應該建立在高度概括的基礎上。過于復雜和過細,不僅會破壞木紋,還會造成視覺上的反差。

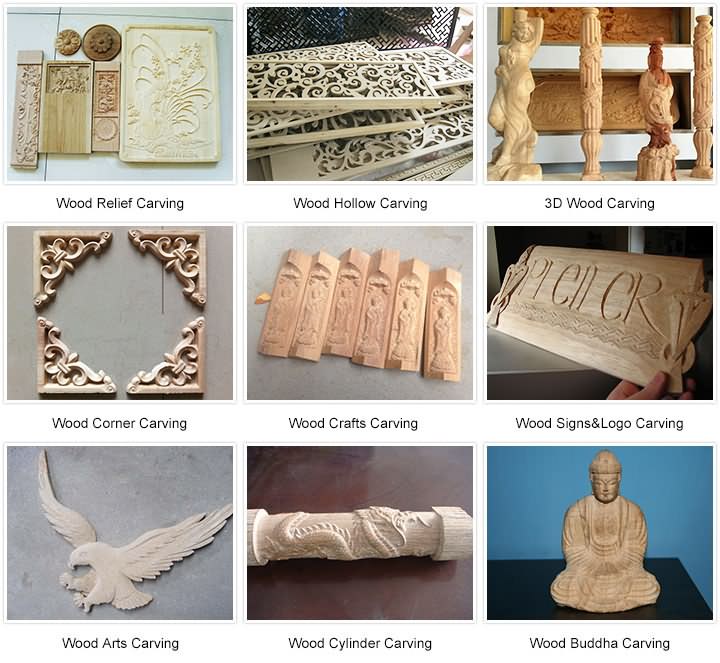

What Is A Wood數控Machine Used For?

Wood數控machine is a kind of numerical control power tool for milling wooden components. It has the characteristics of flexible use, fast speed, good quality and high work efficiency. It can process the edges of strip-shaped workpieces, can also groove and engrave the surface of the workpiece, and can also hollow out the workpiece. If the woodworking engraving machine is fixedly installed on the table, it can also process small and medium-sized wood decorative lines.數控wood routers are widely used for hollowing, cutting, and carving of MDF, fiberboard, particle board, artificial synthetic board, cabinet doors, solid wood doors, craft wooden doors, paint-free doors, screens, craft fan window machining, shoe polishers, game machine cabinets and panels, mahjong tables, computer tables and auxiliary machining of panel furniture products.

In short, when you want to buy數控machines for woodworking, do not just pay attention to the wood數控machine price, the right數控wood router is the most important.